Stratofan is a fan, and as such it may seem like a simple product, but there is a lot of technology to support its outstanding features.

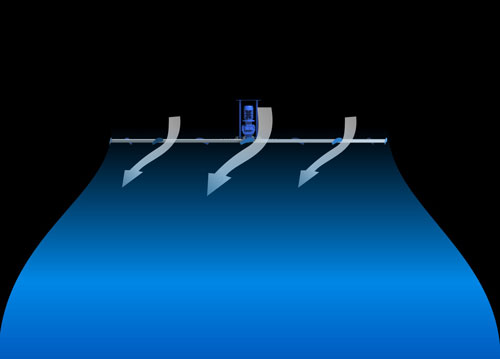

Aircraft-derived blade profiles are optimized to move as much air as possible while rotating at low speed : maximum efficiency, very low power consumption, low noise.

Extreme performance, efficiency and reliability are not achieved by accident: years of experience with products installed in the heaviest industries and hundreds of tests on dozens of different components are the basis for the design of these fans.

Every part of Stratofan is designed and tested to achieve the desired results, each component is selected from the best in its class on the market. Here are some examples :

- The profile of the blades is aircraft/helicopter-derived.

- The number of blades is designed to optimize efficiency, noise and critical frequencies.

- The structure of the blades is box-type to ensure strength with the beam effect.

- The material of the blades has controlled and guaranteed mechanical and chemical characteristics according to European standards.

- The blades are equipped with winglets at the end, designed with the function of:

- Directing air flows

- Reduce noise and swirls

- Increasing efficiency

- The gearboxes are sized with large safety margins and are suitable for heavy-duty service.

- Seals, case material and type of lubricant are carefully selected.

- Electric motors are made in Europe, specifically for inverter power supply.

- The control panel contains only high-quality electrical components.

The blades of Stratofan fans are made of lightweight corrosion-resistant aluminum alloy. In addition to this, special versions are available for more critical environments or outdoor applications:

- Protection with hot-dip galvanization

- Stainless steel package